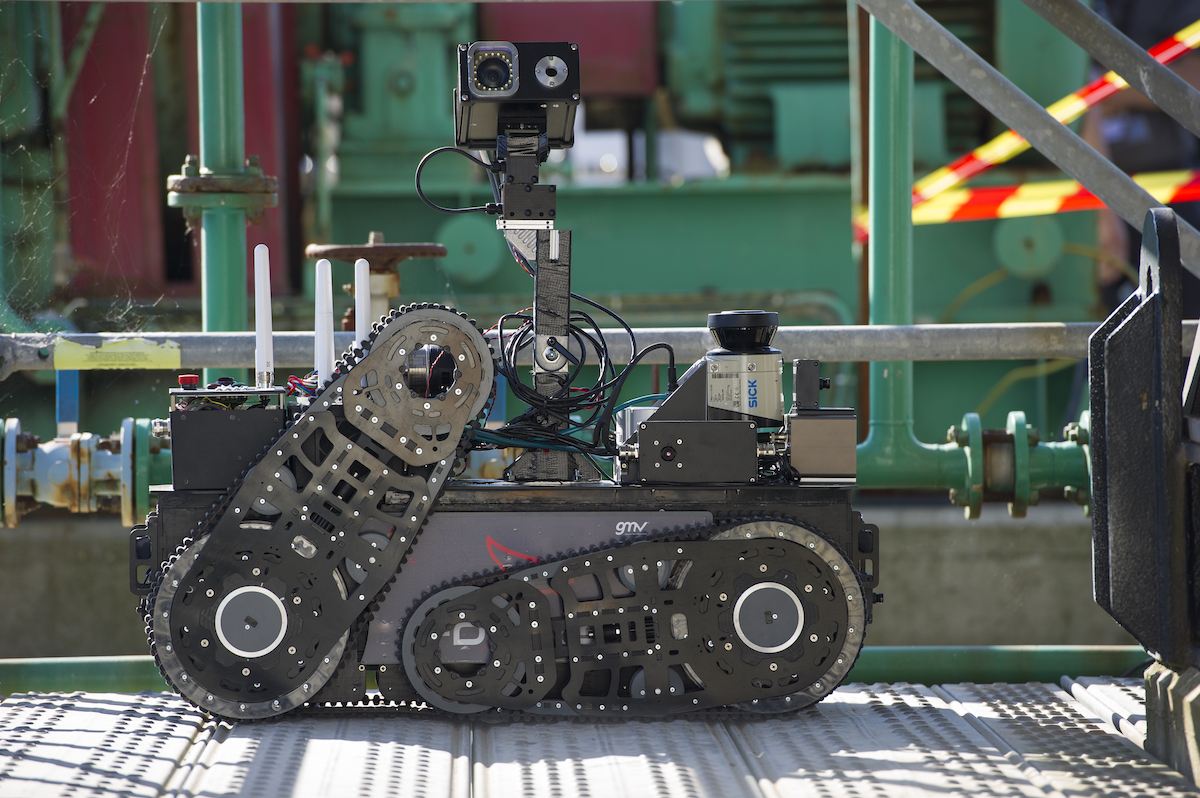

The Foxiris robot, building on ESA’s ExoMars rover and developed by a Foxiris team led by Spain’s GMV is competing in the Total oil and gas company’s Autonomous Robot for Gas and Oil Sites (Argos) Challenge. The three-year competition is encouraging the creation of robots to work on hydrocarbon production sites in extreme conditions.

at Total’s gas dehydration production plant at

Lacq in France during the Argos Challenge in

June 2015. Image credit: Total/L. Pascal

A key requirement for all of the robots in Total’s Argos Challenge is to work in remote and hazardous environments. This includes the ability to navigate around the test plant, through narrow walkways and climb the stairs. The GMV Foxiris robot measures 35×90 cm, with a camera on a telescopic mast that can reach up to 1.8 m. Foxiris carries internal navigation sensors and scientific instruments including cameras, thermal imagers, gas sensors and microphones. These allow it to inspect and monitor pressure dials, valves and level gauges, detect hot surfaces, sound alarms and localise gas leaks. The robot was developed by a team consisting of technological business group GMV, robot specialist IdMind and Universidad Politécnica do Madrid (UPM-CAR).

Total envisages that autonomous robots will in future strengthen operators’ safety by performing routine, repetitive tasks such as inspections, as well as detecting anomalies, alerting operators and intervening in emergencies. GMV’s Foxiris consortium was one of five teams chosen for the competition. Kris Kydd, Total’s Argos project manager explained:

“We want the robot to be able to move anywhere on a production facility that a human can go today. Then, using artificial intelligence, we want the robots to be able to read and record the values on the instrumentation, and to know autonomously whether they are normal or not. If there is an abnormal situation, the robot has to alert the remote operator.”